Common question most 3rd engineer or ETO normally ask is “how to properly adjust boiler steam pressure controller?” maybe to work on auto operation, give high or low steam alarm, etc.

Probably,the same question might be on your interest right? so read on.

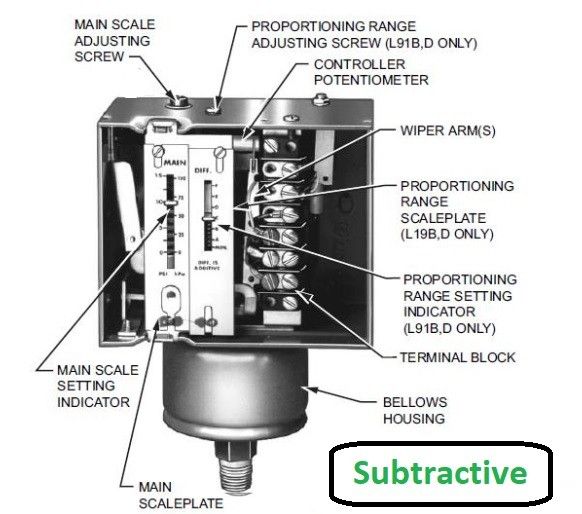

Adjusting boiler steam pressure might seems simple, still it is sometimes confusing if you are not well familiar with the controller poles. There are two different types of pressure controls for a steam boiler ie: Additive type and Subtractive type . Lets start by explaining this two controller types.

How to determine the type of boiler steam pressure controller which was intstalled on your boiler

In other to determine if the pressure controller system installed to your boiler is an additive system or subtractive system, you have to check on the scaling design. Normally, if the front panel of the controller state either “Cut In” and differential scale inside that is additive. While a subtractive system will show main scale “Cut Out” and differential scale close to it on same front panel (cover).

Additive type of boiler steam pressure controller

On additive type controller or pressure switch, the setting and adjustment are quite different, Cut off and Cut in of the boiler are adjusted following the scale number on the front cover, while the Inside cover scale is the Differential setting.

Lets take for example we want to operate our boiler between 5 and 8 bar, we will set the Cut in for 5 bar( following the front number), then remove the outer casing of the Controller to access the differential dial using a screwdriver, there you can adjust the Differential scale to 3 bar. Lets say your divce is on PSI, then another example: If your Main scale PSI is 3, which is where the boiler burner will start up, the boiler burner will turn off at between 5 and 8 PSI based on how the differential scale is set.

Subtractive type of boiler steam pressure controller

Subtractive type of boiler pressure switch is one of the most common type of pressure control switch use onboard ships. according it standard, you can adjust the pressure switch for the required pressure where you want to cut off the boiler burner.Onbord most bulk carriers and container ships were only fuel oil and hot water are heated, i use to set it at 4-6 bar. While the differential setting is the pressure where the boiler burner will cut in and the main cut off pressure.

Note, the more wider the differential, the better the efficiency you will have. I do recommend to set the differential pressure 2-3 bar in such rang of pressure(4-6bar), depending on your required pressure, you can make up what differential pressure to set. Also note If set the differential pressure too wide, your steam pressure might drop lower below the temperature you require for your operations, therefore make sure to keep little rang.

conclusion

Apart from the steam pressure controller, there are also “Limit Control” which can also protect the boiler burner in case of a runaway boiler. The limit control system normally, has small “Manual Reset button” inside or on top of the cover. The limit controller can also be set little higher than the steam pressure controller. If the steam max. is on 8PSI its recommended to keep limit control at 10 to 14 PSI to be on the safe side.

Both controllers work in same form, which means, you start up the boiler auto and allow the pressure to build up. Once the pressure reaches a set point; for example 8 PSI, the boiler burner cut off (stop). The boiler burner stays off until the pressure inside the steam drum drops to the set differential minus 3 PSI, then boiler start up automatically. In this case you will reduce fuel consumption and continue manual stop and start stress.

Related read : 5 Main Reasons Why Boiler breaker trips or Fails To Fire

Hopefully this article helps you solve any problem regarding boiler burner controller. Do subscribe to our newsletter and share with friends who might found this article interesting….