Since the integration of industrial electronics into marine engineering systems adding to the giant strides made in the development of computer technology, it has become possible to re-introduce the fuel injection common rail along with other fuel injection systems, using this modern technology to time the injection of fuel without mechanical operating method which has been in the system for long.

Having conducted different types of experiments, tryouts, etc, it has become possible to dispense with the timed camshaft altogether by using similar systems to control the operation of valves, the air start system, and air supply.

However, in this article, we will compare the features of the two main manufacturers of the marine electronics engines system, placement, and functions.

These two major manufacturers of two-stroke crosshead engines have both introduced a camshaft-less engine (Electronic engine).

- Sulzer Introduces theirs and called it RT Flex engine

- MAN B&W the popular use marine engine also introduced theirs and called ME intelligent engine.

The working principle is all the same, it’s only matters of position, programming range, and design.

The difference between RT Flex engine to that of ME intelligent engine

In fact, both engines use electrical and engine driven axial piston pumps to pressurize servo oil rails to 200 bar which are then used for fuel injection and exhaust valve operation.

In addition, MAN B&W use the servo oil to drive the cylinder lubricator units (Alpha system)

Although they both work without a camshaft and use computers to control, fuel injection, exhaust valve operation and air start, the method of fuel injection are different.

Wartsila RT flex engine as shown video by brian all right reserved

Sulzer uses a pressurized fuel rail using a set of jerk type pumps driven by a three-lobe cam geared to the crankshaft.

The pumps are variable delivery, based on the ZA40 fuel pump, controlled by an electrically driven fuel pump shaft linked to the engine computer. The MAN B&W ME engine does not operate the fuel injection on a common rail system.

Learn more about the Electronically controlled Engine by MAN B&W

all right reserved

What are the concept behind

Electronically controlled Engines?

- Fuel economy – The major idea was to reduce fuel consumption which may be caused due to mechanical wears, as well as to the cost of maintenance. Actually, the electronics may be expensive, but not up to that of the mechanical spares.

- Flexible operations -The electronic control engine second concept was to give more flexibility to the engine operation; Example: in terms of smooth and immediate reversing action without reconnecting camshaft, easy and smooth starting of the engine, it lower engine revolution along with good slow steaming capacity.

- Convention requirements – These engines were meant to maintain the EIAPP conventional operation by easy adjustments, monitoring, etc.

Conclusion

Having work onboard ship with both ME intelligent and RT-flex, I found no much difference, except the positioning as said before. Both have one major problem which is fault location finding.

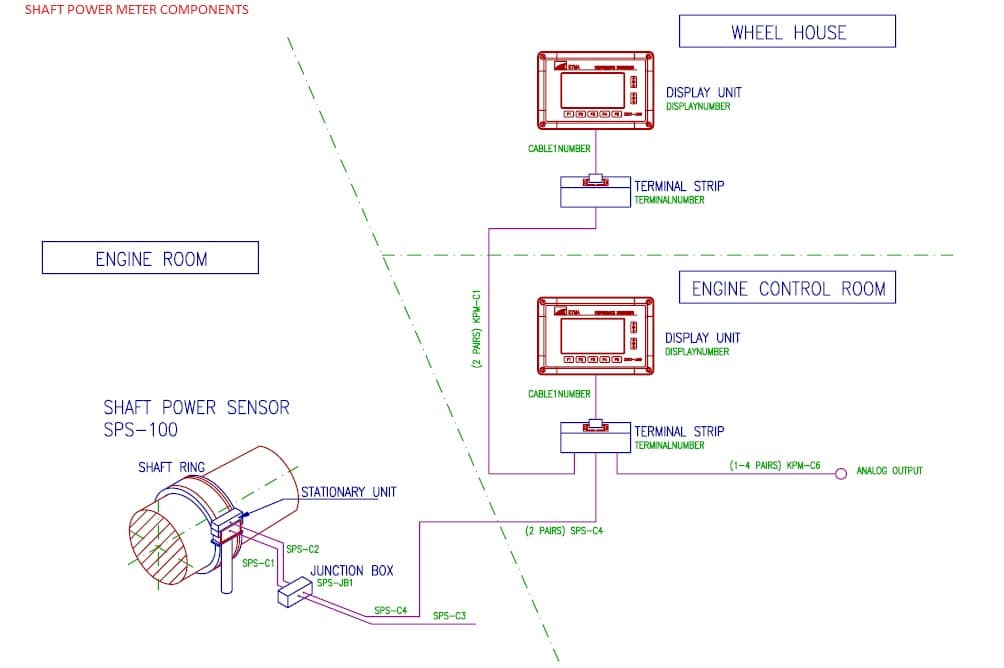

Let’s say you got alarmed in the Engine control room (ECR), which indicated that on injector controlling sensor is faulty, sometimes its very difficult to locate the actual sensor if you are not really familiar with the system. That is why most ship management and owners always request for an experienced engineer who has worked on say system before. Therefore I advise you to watch videos, read more about the system, never guess on the system.

We hope this article will be useful for your search and career. Found this post useful? subscribe to our newsletter and share with friends who might need it.

1 thought on “RT Flex Vs ME intelligent engine”

This is really helpful. Thanks for this