Keeping regards of your marine engine crankshaft deflection is very necessary. It helps you to determine when your engine crankshaft deflects to either positive or negative.

In this article, we will like to discuss shortly on what crankshaft is all about, why do we really need it and as well learn proper ways to take readings.

Crankshaft deflection definition

Firstly, how can we define crankshaft deflection; This is a measurement done on engine crankshaft by placing a dial indicator gauge across the center of the crank webs. While turning the engine clockwise or counterclockwise, the dial indicator defines the condition by showing both sides vertical and horizontal point readings.

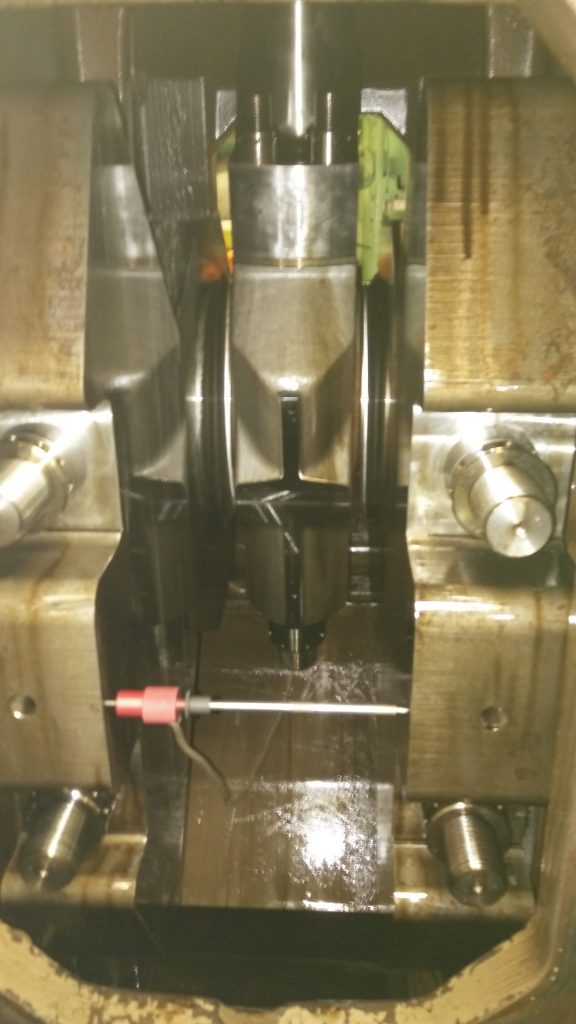

These readings can be compared to the manufacturer recommended limits. Using Wartsila engine as an example shown on below image, it lets you understand the point were to take your readings.

Also, learn more on common Starting Problems On Marine Auxiliary Diesel Engine

We take crankshaft deflection to make sure that the crank runs and maintain proper balance. As you may know, the engine crankshaft comprises of the Journal, crank pin, and crank webs; these are all supported by the main bearings via the Journals. Therefore as the engine runs, due to some friction between the bearings and crank pin, the bearings wear out and maintain imbalance across the length of the crankshaft.

When this occurs, you experience high readings which will indicate the actual position ( either closed or open).

Well as I said earlier, to make this article short and understandable, I will like to explain how to take deflection readings of your main or auxiliary engine crankshaft.

How to take crankshaft deflection readings?

Below steps are to follow to accomplish proper readings ;

- Sent your dial indicator to zero

-

open all crankcase covers

-

Engage turning gear

-

switch your turning gear to manual (if in auto)

-

Turn the engine till the crank web horizontal to point ( to enable you to place dial indicator at a proper point)

-

After placing the dial indicator, check to make sure it’s at zero ( set again if required) then to top port-side (TP) take your readings ( between -0.01 to -0.35 and +0.01 to +0.035 …. see manufacturer recommendations)

-turn back to initial point “P” ( port-side or starboard side horizontal, depending on which side you started) take horizontal position reading.

- turn to the bottom “B” also take readings.

-

Keep turning till starboard side horizontal (S) take readings

-

continue turning till top starboard side vertical ( TS) then take final readings.

Repeat the above listed to all units and record as required.

Related post: 8 Main reasons why marine engine not starting or turning

Check your engine manufacturers guide about the appropriate standard.

For any questions, please drop it on the comment box below or contact us for more guidance. Hope this article helps you.

The above program will guide you for easy calculate evaluate the engine alignment and main bearing wear.

Watch the short video regarding how to take crankshaft deflection to learn even more

How do you take your engine crankshaft deflection? drop your recommendations on the comment box below.

Would you like to read from us when we publish new articles? If yes, kindly subscribe below for more updates.

[…] You might like to learn more about the difference between marine engine Turbocharger vs Supercharger […]

[…] contact us for an invitation and other consultation regarding […]

[…] in terms of 3rd mate and 4th engineer, the top rank(eg: chief engineer and captain ) are always on…

[…] When your name is been searched by a recruiter and found out that your resume is all over the…

[…] for a couple of days only to investigate and find there were two major leaks in the steam lines…