On board ship, there are major separation or purifiering methods and it’s important, which crews need to understand the basic principles behind them.

This article will point out three major purposes of separation, types of separation and give more explanation of the basic things to know before using any of the separating equipment.

The Purpose of separation

There are three major purposes of separations;

- Concentrate and separate solid particles from a liquid

- To free a liquid of solids content

- Separating two mutually insoluble liquids with different densities, while taking away any solid presents at the same time.

Related post: 4th Engineer Duties and Responsibilities

The above mentioned can be achieved in different ways. Following experience and experimental results, it’s given that we can achieve the above basic principles of separations by ;

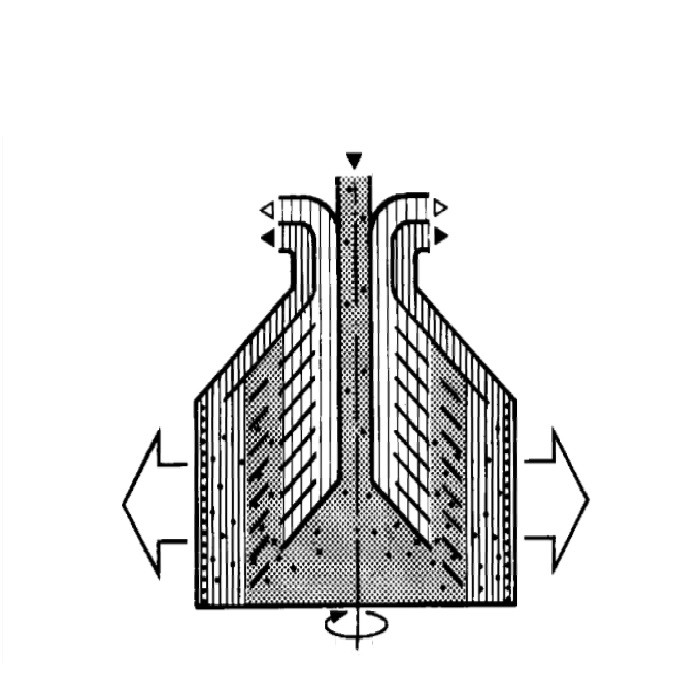

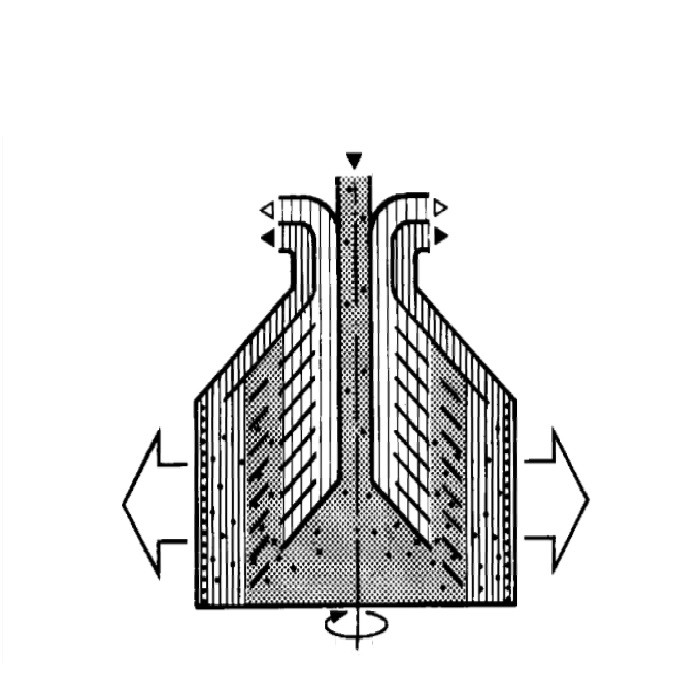

- Centrifugal separation

This is mostly used on board ship, to separate fuel oil from water and/or sludge by rapid rotation of the bowel, in such a way that the force of gravity is replaced by centrifugal force which is of thousands of times greater.

- Gravity separations

We can also achieve separations of the liquid mixture in stationary bowels; eg. bunker tanks. This liquid gets cleared slowly as the heavy particles in the liquid sink downwards to the bottom due to the influence of gravity. This particle can be removed by placing a drain below the bowel.

- Temperature Separations

Since on board ship and in general, we do have some liquid which requires a change of temperature ( eg. Mineral oils), therefore high separating temperature increase such liquid capacity of separation. This type of separation can be divided into two bases on there states

a) High and low viscosity

b) High and low density

Following the above explanations, on board ship was equipped with an already modified purification system, which follows the above steps to help the operators in quick separation and easy operations. Instructions are also provided for the operators to follow to avoid injury due to high speed or temperatures.

Also, see What is the difference between purifier and clarifier?

To achieve the desired separations, you must follow the instructions of each manufacturer and safety guides.

We hope this helps or insightful to you. You can share your idea or additions to the topic (if any). Share to reach friends who may benefit from this article.

Share this:

Related post

4th Engineer duties and Responsibilities

4th Engineer who is a licensed member of the engine department onboard a merchant ship is as well the first rank promotion of the engine department. Moreover, the fourth engineer rank is very stumbling upon by a lot of responsibilities, which need to be completely satisfactory. According to the ranking…

MARPOL 73/78 Laws Guiding OWS

Oil water separator ( OWS ) is a useful tool for separating oily bilge waters to avoid water pollution. On this article, we are going to look into MARPOL 73/78 laws guiding OWS. Lately, 70's, most ocean-going ship directly pump out oily waters into the ocean, which eventually flow down…

Ship Oil Purifier not reaching normal RPM Reasons

Have you ever start an HFO or Oil Purifier and it never gets to it normal RPM? Are you in a problem with why your Oil separator refused to run properly after it reached to required rpm? Don't worry, I'm to guide you through step by step on how to…

1 thought on “Basic Tips for Purifier Working Principles”

Pingback: 10 Major Source Of Fire Out Break Onboard Ship - Marine And Offshore Insight